# Products

01.10.2024

Bayblend® CTI featured in Metz Racing Team’s Electric Vehicle

Improvements thanks to the latest material

This marks the second year that ALBIS has supported the Metz Racing Team’s transition to electric propulsion. “In 2023, the team faced challenges when machining the battery plates, prompting ALBIS to provide an improved solution for this year’s competition,” says Romuald Muckli, Business Development Manager at ALBIS.

The chosen material, Bayblend® FR CTI, has recently been introduced by Covestro. Together with Makrolon® FR CTI, it is part of a new product range developed for electrical vehicle (EV) and electrical and electronic (E&E) applications, specifically for systems with a voltage of 600V or higher.

Cooperation with manufacturer

The collaboration with Aplast, a specialist for the production of semi-finished products through an extrusion-compression process, has significantly enhanced the manufacturing quality of the plates. This process eliminates the risk of unmelted granulates, ensuring flawless machinability.

“Each year, the students design a new type of vehicle, and using plastic injection to produce the battery components would be quite expensive,” explains Romuald Muckli. “What is more, the required investment would hinder the annual evolution of battery configurations, stifling improvements and innovations.”

In this project, Aplast Manager François Lagrange demonstrated the effectiveness of the company’s process when manufacturing thick plates and other semi-finished products. The productive collaboration and the shared commitment to quality has provided the Metz Racing Team with materials that meet the high standards of the competition.

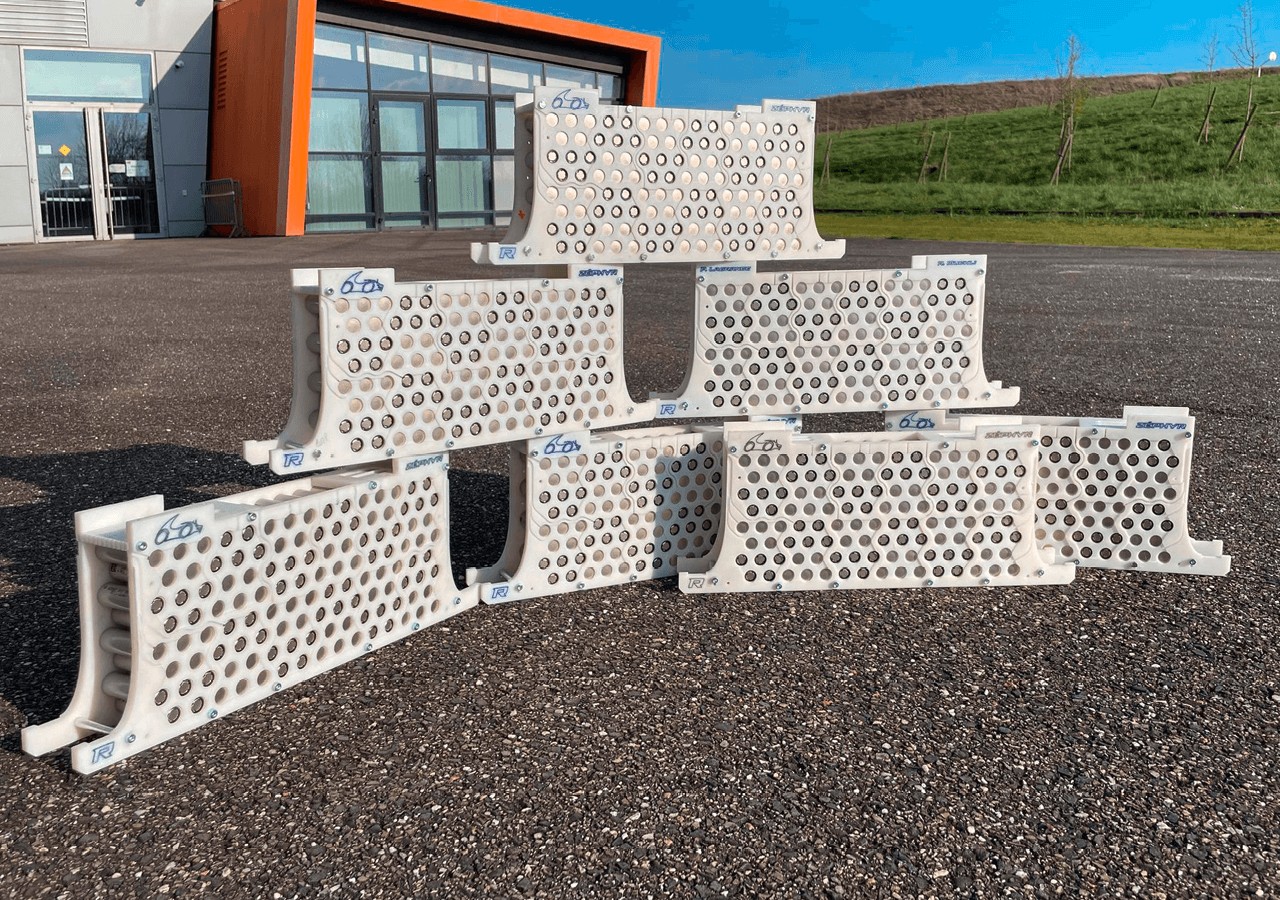

Cells and cell holders of the battery

Assembly of the battery´s five modules

Safe, high-performing, lightweight

Florian Vignale, Head of the Metz Racing Team's electrical division, confirmed that the new material performed well in the manufacturing process and met the competition's stringent requirements, including a V0 classification under UL94 for flame retardancy. The chosen Bayblend® FR CTI grade provides insulation against leakage currents at voltages up to 600V, ensuring both safety and performance while maintaining dimensional stability at battery operating temperatures up to 60 °C.

In contrast to conventional materials that meet these requirements, Bayblend® FR CTI does not require fiberglass reinforcement, which significantly reduces the weight. Building tomorrow's cars and means of transport also means thinking light to improve performance, reduce energy consumption, and minimize environmental impact.

More information

If you would like to find out more about this range of products, you can watch the related webinar by ALBIS or download the presentation given on this occasion.

Link to Webinar recording and presentation.

Or are you curious to see what this year's race looked like? On LinkedIn you will find a video with the “best of” the three days.

About Formula Student France

The Formula Student France competition brings together students currently undergoing automotive engineering training. They must build a single-seater formula-style car to compete with teams from around the world. The international design competition is not won solely by the team with the fastest car, but rather by the team presenting the best overall combination of construction, performance, and financial and business planning. Teams immerse themselves in the role of a manufacturer by developing a prototype for evaluation and potential production. The car must exhibit excellent driving characteristics such as acceleration, braking, and maneuverability. It must be offered at a very reasonable cost and be reliable. The market value of the car increases through other factors such as aesthetics, comfort, and the use of easily available standard purchased components.

Teams will be judged by a panel of experts from the motorsport, automotive, and supplier industries. The jury will assess each team’s car and sales plan based on construction, cost planning, and business presentation. The remainder of the evaluation will take place on the track, where students will demonstrate how well their self-built cars perform in their real-world environment through a series of performance tests.

https://fs-france.com/